Application: Use on race track only

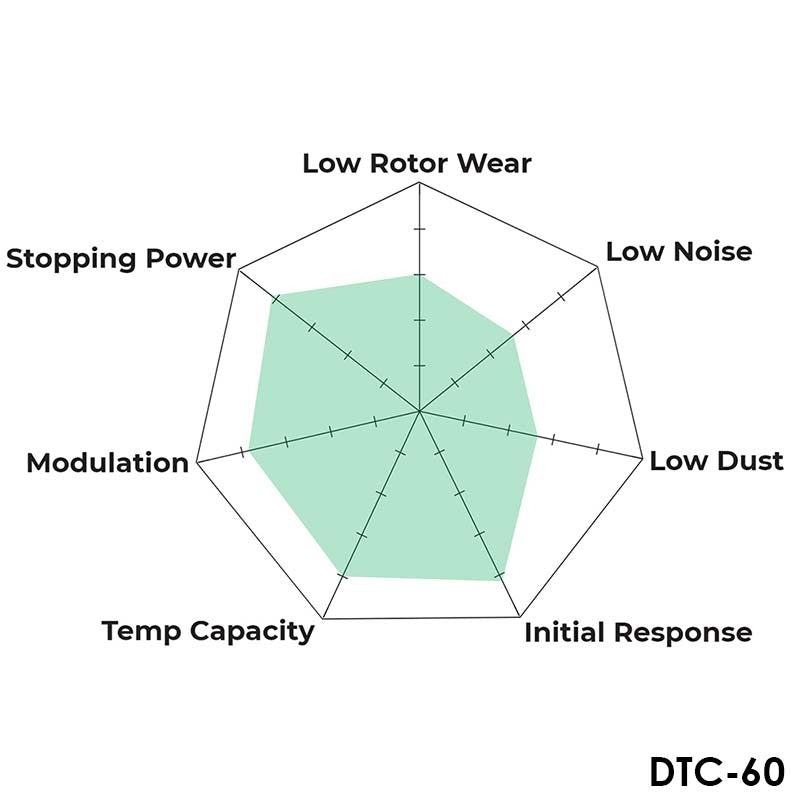

High torque compound with less initial bite than DTC-70. Superior release and torque control characteristics. Designed for cars with high deceleration rates, with or without downforce. Recommended for use with DTC-70 when split friction between front and rear axle is desired.

Running with extremely high deceleration rates and increased downforce poses different challenges, so Hawk designed DTC-60. Recommended with DTC-70 when split friction between axles is desired, it has excellent modulation and release characteristics.

Characteristics

- Superior release and torque control

- Very low abrasive rotor wear

- Popular choice on lightweight front axle applications, with or without ABS

- Applicable to NASCAR/NASCAR modified, ARCA, Super Late models, pavement circle track, Pro 2/Pro 4 Off Road Trucks/Pro Lite, Sports Car/GT/GS, Open Wheel/Formula

- High torque

- 400-1600 F operating temperatures

- 700-1100 F optimal temperature range

- Less Torque and Initial Bite and Compared to DTC-70

- Provides Outstanding Lighter Weight Vehicle Performance

- Perfect for Drivers who Prefer Split Friction Levels Between Front and Rear Axle

- Excellent Release and Modulation Characteristics

Note: All Hawk Performance compounds are not compatible with carbon ceramic rotors. Hawk pads are designed to work with Iron/Metal rotors.